NEWS

Pollmeier invests in quality and sustainability and integrates high-tech quality and optimization scanners from enigmasoft

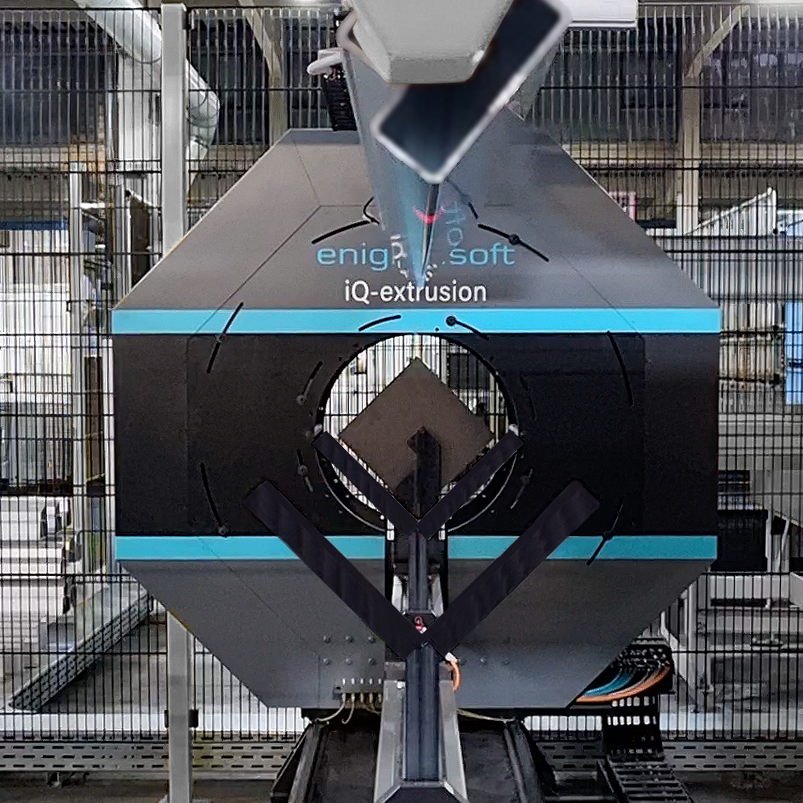

iQ-extrusion / High-end optical measuring and inspection system for aluminium profiles

OEMs demand complete and documented 100% measurement and inspection of every delivered component with regard to geometric dimensions, quality and presence of machining, and surface quality. iQ-extrusion combines all these requirements in one system. Uncompromisingly fast and precise!

Online article, International Aluminium Journal: https://www.aluminium-journal.de/optische-high-end-messanlage-fuer-aluminiumprofile

iQ-360 / Patented optical measuring and inspection machine impresses the wheel industry

Our patented solution makes it possible for the first time to measure and inspect the design side and the brake disc-facing side of a wheel simultaneously with high accuracy and very quickly in one measurement and inspection cycle.

Additional iQ-specta scanners (1xRIP/2xCHOP) delivered!

One RIP scanner (top & bottom/quality and cutting optimization on the board) and two CHOP scanners (4-sided/quality and cutting optimization on the lamella).

They are controlling a very large high-performance cutting system for solid wood “as a trio” and will sustainably increase and stabilize the wood yield.

Crowded house!

Many high-end measuring and inspection systems from our iQ product family before delivery

Optical inline measuring and inspection systems

Highest measurement and repeatability accuracy in the micrometer range

100% measurement and inspection of every single profile before delivery. Directly in your production line. Uncompromisingly fast and precise. The use of our high-end measuring and inspection system iQ-extrusion enables you to significantly increase and stabilize the high safety standards and product quality. We digitize and measure both fully and over the entire surface as well as to RPS.

iQ-360 in a trio combination

Highly accurate Measurement and 100% inspecting each individual wheel. Uncompromisingly precise!